the system

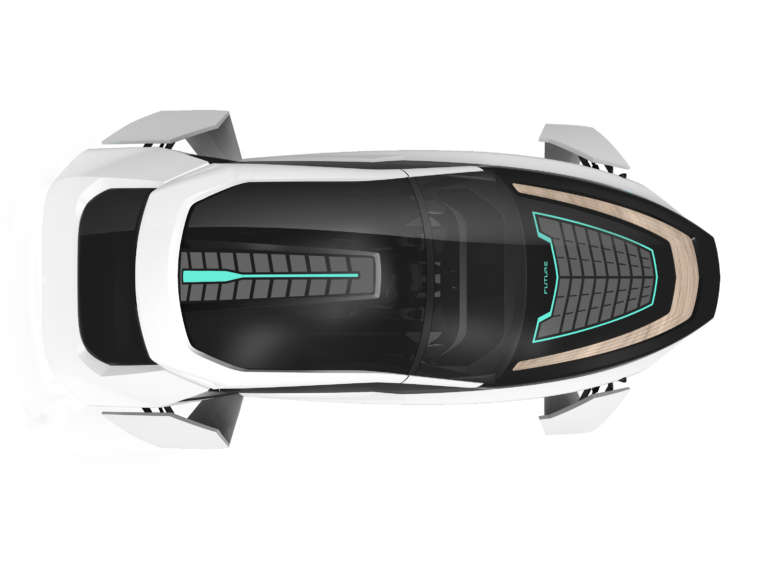

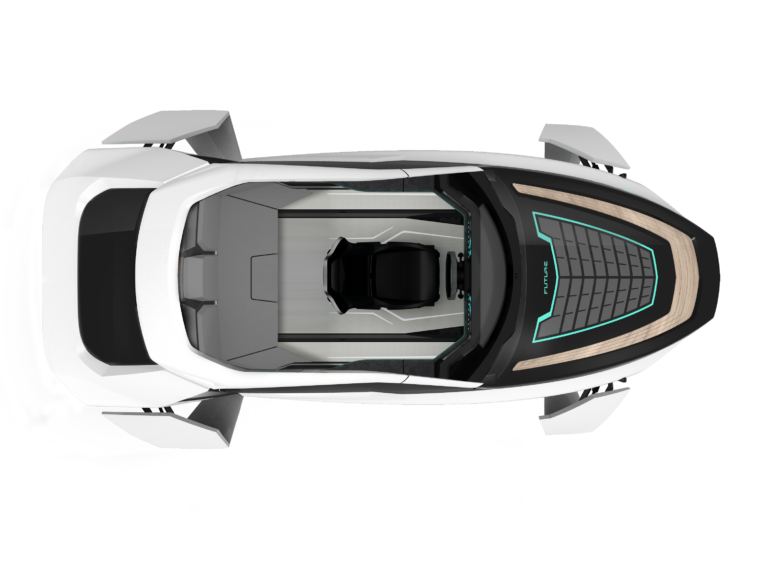

FUTUR-E combines technology from the boating industry, car design and aviation with an integrated kinematic system of automotive inspiration, similar to Formula 1 car suspension.

The kinematic system in particular manages in synchro, with electro-hydraulic actuators, the movement of the foils with independent dynamics, under the control of a single control unit, equipped with a gyroscope, which set up each element.

The mechanical kinematics are plug and play, can be installed indifferently on one of the 4 foils provided, it does not have openings towards the inside of the hull, making maintenance accessible even when the boat is launched in the water.

The handling is very similar to a comfortable sports car.

design

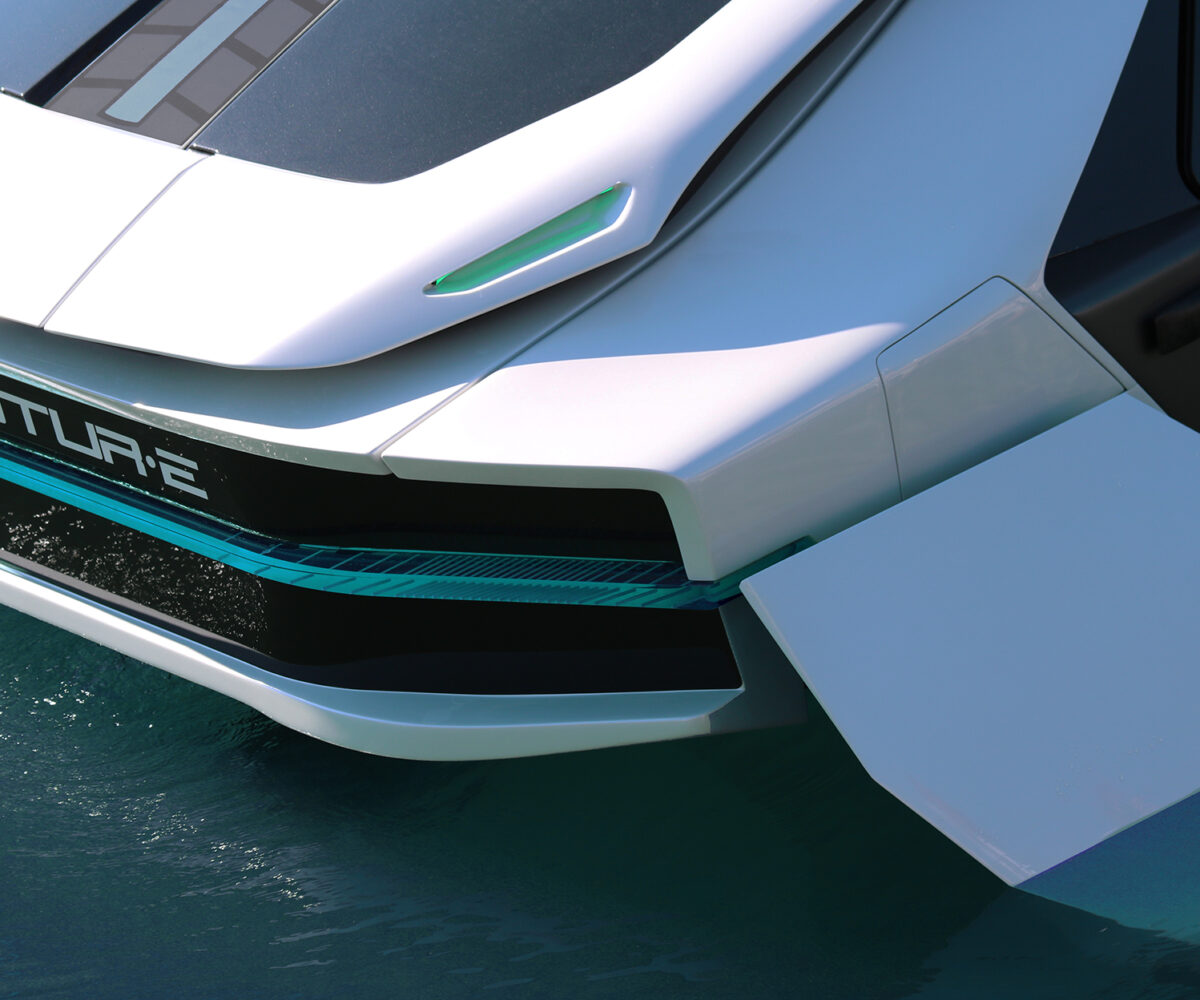

You have seen flying cars in science fiction movies, but you haven’t seen a flying power boat yet. With an Avant-Gard boat design vision FUTUR-E hull – or better body – is styled to look like a supercar.

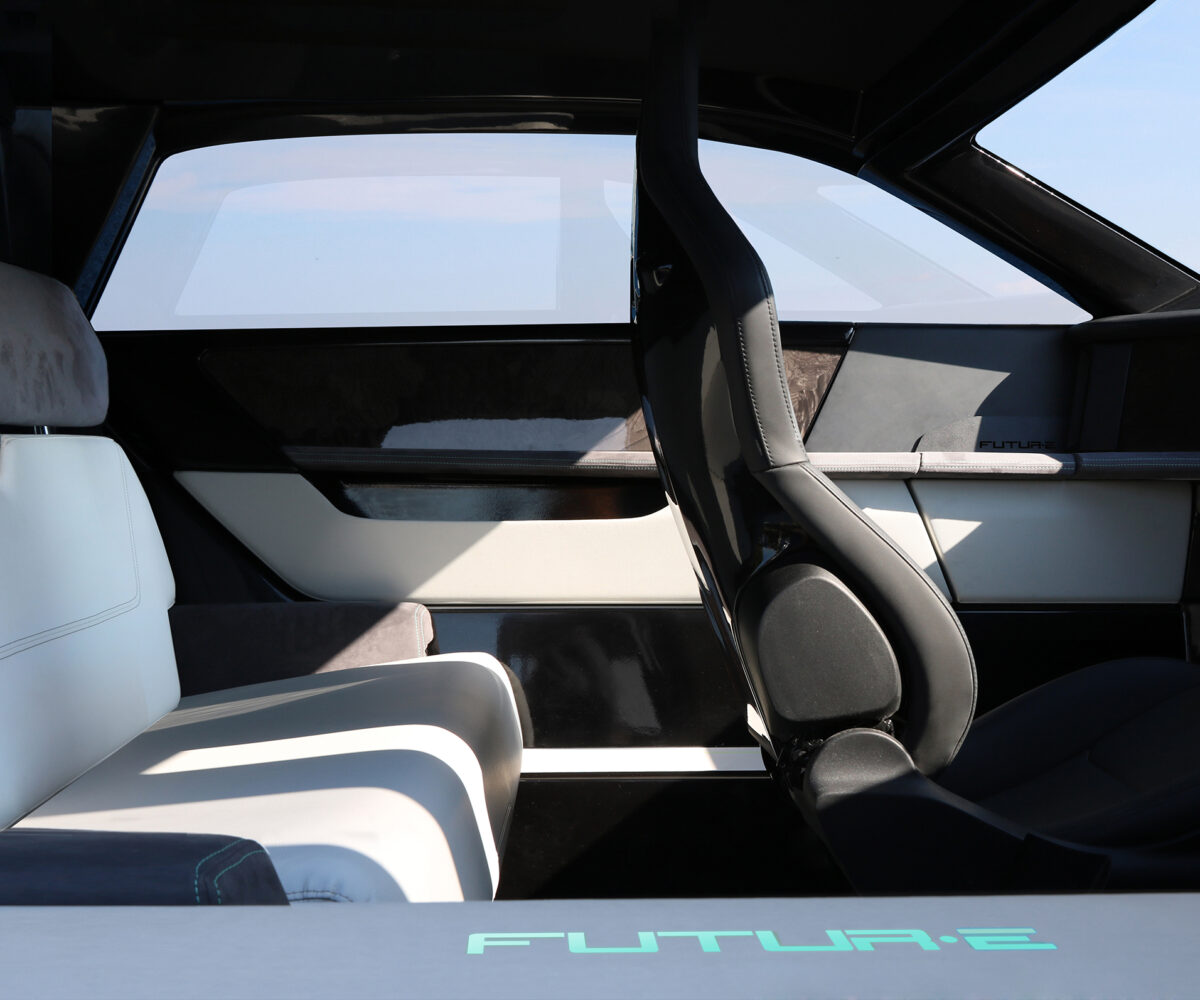

The foils are perfectly integrated in the outline of FUTUR-E limiting their clutter into the shape of its body. The foils shape serves also as cradle to store FUTUR-E on the deck of a superyacht or on any land surface. The futuristic interior can host the pilot and three passengers.

The dashboard is a perfectly successful combination of wrap-around screens. All the navigation and motor data are ergonomically under the pilot’s eyes.

Specifications

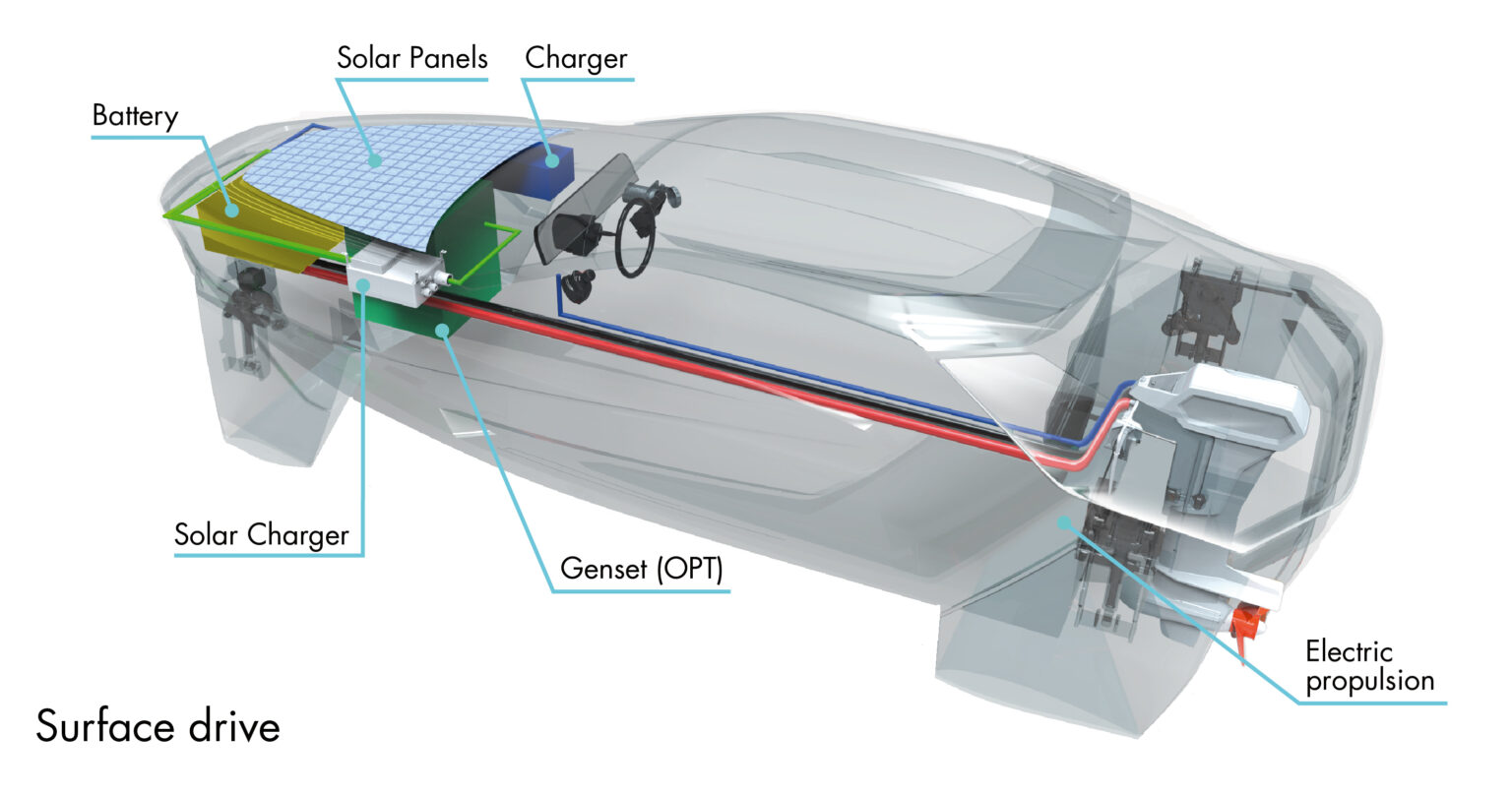

For the power trains there are two options. Outboards engines or inboard engine coupled with surface propeller propulsion system.

With variable power packages options, FUTUR-E can reach a maximum speed over 30 knots.

As the boat speed increases, the foils start to lift FUTUR-E, like an airplane on a runway, when it reaches 8 knots the Foil Assisted Mode starts and at 16 knots it enters in Full Foiling Mode minimizing the water drag.

Foils provide a high grip in the water, enabling to maneuver like no other boat.

They are designed to provide auto-stability to ensures a very comfortable ride, by removing the movement generated by the waves impact on the hull.

Length overall

5,2 m (17′ 1”)

Beam overall

2 m (6′ 7”)

Construction Height (Planning Mode)

1,4 m (4′ 7”)

Construction Height (Foiling Mode)

1,9 m (6′ 3”)

Displacement (Lightship)

1580 kg (3483 lb.)

Displacement (Full Load)

2000 kg (4409 lb.)

Eco

FUTUR-E is an eco-boat. Its structure is built in carbon ber produced from 100%

recycled ber with recycled structural foam reinforcements.

The foils and rudders are also manufactured in carbon fiber.

All the elements are recyclable.

The electric motors guarantee a zero-emission mode.

Zero Emission

FUTUR-E is a zero CO2 emission, zero noise, zero wave boat.

The electric propulsion doesn’t generate any air pollution.

The foils of FUTUR-E lifting the hull above the water, reduce the waves, creating a very smooth ride helping to consume less energy and allowing to travel on rougher waters with reduced drag, while keeping the passenger cabin highly comfortable even preventing sea sickness.

The combination of the two systems, electric propulsion system and foils, reduce the navigation noise.

High Technology

The foils and the hull were tested and developed with simulations in virtual towing tank (CFD), where all the ow characteristics and physics are captured. The Foil Integrated Kinematic System is able to simultaneously manage the cant (opening) of the foil and the rake (incidence).

The mechanical kinematic mechanism is plug and play, has no openings throw the hull interior, making maintenance accessible even when the boat is in the water. An advanced 6 degree gyro system monitor the boat performances at different speeds with the system dealing with a large matrices of force data for each foil to control the operating conditions of the boat.

Energy Efficient

FUTUR-E is smooth, comfortable and stable rides that makes it much safer than regular boats.

FUTUR-E is surprisingly easy to drive and can sail at maximum speed even in rough seas.

In extreme conditions, you can retract the foils and use it as a classic boat.

FUTUR-E is an exclusive and unique toy to move around the harbor.

About Us

Davide Cipriani

CEO of Centrostiledesign. He mainly deals with yacht design, developed from a love for boating since his childhood. He became passionate about the design world and soon began his career in the 27-year-old family industrial design business, focusing on marine industry. Davide now manages the company, leading 40 employees and dealing with many customers.

Massimo De Luca

Aerospace Engineer graduated in Palermo, specialized in Naval Engineering in Poland. Member of the design team of +39 Challenger in the 32th America’s Cup, has been responsible for the Naval Architecture and CFD analysis for important shipyards as Ferretti Group (Italy) and Palmer Johnson (Monaco).

In Centrostiledesign is responsible for Naval Architecture and Project Management.

Alessandro Resta

CEO of FUTUR-E FOILING. Mechanical technician specialized in shipbuilding. Since 2004 in Centrostiledesign where he manages the Plug and Mold Department. He is in charge of the Purchasing Department, the CNC Division and the Mold Department, leading 20 technicians. In 17 years of career he has worked on a huge number of projects for most of the international shipyards.

Contacts

FUTUR-E FOILING S.R.L.

Via Ercolani, 5c

40026 Imola (BO)

contact@futurefoiling.com

P.I. e C.F.: 03950831200